The Benefits of Successful Graphene Dispersion

Graphene’s two-dimensional structure in platelet form results in a high aspect ratio, high surface area nanomaterial that has the potential to offer transformative benefits to many industrial products. However, only with the correct incorporation into a host material can industry truly benefit from the outstanding properties that graphene has to offer.

Even the highest quality nanoplatelets will fail to provide any meaningful benefit if they are not distributed correctly in the end formulation to which they are added, so achieving this is essential for their effective use in real materials engineering applications.

The Challenges of Graphene Dispersion

Lightweight powder forms, including graphene nanoplatelets, can be physically problematic to handle in a product manufacturing environment. Engineering the dispersion process to fully encapsulate the powder particles within an additive carrier helps to prevent the release of free graphene particulates during both downstream manufacturing and final product application. However, working with powders that are also difficult to wet and stabilise brings the added challenge of preventing the separated particles from restacking and forming agglomerates or sediments during storage or when mixing them into other liquids.

The fundamental approach of graphene dispersion is to break apart solid agglomerated materials down to their primary particles and stabilise them in the carrier matrix. Once dispersed, the individual particles are held in suspension within the dispersion medium. However, as with other forms of carbon, such as carbon black pigments and graphite, graphene nanoplatelet particles have a natural affinity for themselves and, if not properly stabilised in dispersion, will tend to re-agglomerate.

A major challenge that graphene nanoplatelet dispersions present is, if agglomeration does occur due to poor stabilisation, the redispersion of these particles can be very difficult. When the graphene nanoplatelets agglomerate they often join together at the lateral, flat interfaces of the particles, resulting in the few atomic layer thin platelets restacking on top of each other. Therefore, failure to fully disperse and stabilise graphene nanoplatelets, not only can result in the formation of clusters of graphene nanoplatelet particles but, through restacking of the nanoplatelet sheets, graphite particles can quickly form.

The goal is to engineer dispersions so that the graphene nanoplatelets are broken down to their primary particles as much as possible, individually separated and stabilised. In this way, a high quality, stable dispersion can be achieved with reduced risk of sedimentation or flocculation of particles. This additive dispersion can then prove useful as a delivery media for the graphene into the end product, maximising the opportunity for achieving a well-dispersed array of nanoplatelets in the end product formulation.

Benefits of Dispersion

If powders are properly dispersed and stabilised, the final formulation is more likely to offer consistent properties, higher levels of performance and longer shelf life. Well-dispersed systems are also easier to incorporate, and likely to be more compatible with other materials, overcoming some of the perceived difficulties with the incorporation of graphene into existing systems.

When correctly used, the value-adding properties of graphene can be transferred, such as low permeability, high strength, improved barrier and thermal and electrical conductivity.

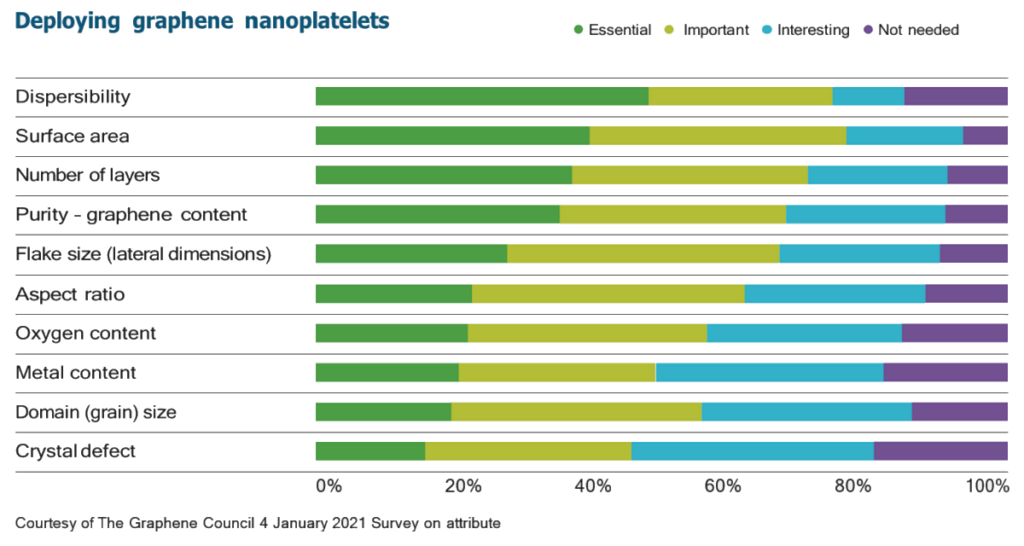

Research from The Graphene Council has shown that the processing and handling of graphene is integral to achieving success in an industrial application.

Successful dispersion is one of the keys to unlocking the true potential of graphene as an advanced nanomaterial.

Applied Graphene Materials UK Ltd. (AGM) is leading the way with this, enabling the consistent supply of high quality graphene dispersions that are safe to handle and easy to incorporate into real world industrial products.

Dispersion Expertise

AGM supplies user-friendly graphene dispersions in various solvents, resins and water-based solutions, allowing formulators and materials engineers to add graphene nanoplatelets in a liquid carrier that is suitable for their individual systems. This flexibility makes it convenient for its customers to benefit from the properties of graphene in a repeatable, consistent manner at volume and in a real production environment.

To learn more about how dispersion technology could enable you to bring a graphene-enhanced product to the market, contact the team at info@appliedgraphenematerials.com or call +44 (0)1642 438214.