Case Study

Updated July 2022

Outstanding Corrosion Protection

Enhanced Adhesion Properties

Significantly Reduced Blistering

Preventing Narrowboat Corrosion Using

Genable HC Primer

The Setting

While canals and waterways are home to many stunning narrowboats, a barge’s steel hull can begin to rust if they are not regularly maintained by owners.

Re-painting above and below the waterline is a necessity to prevent corrosion if the shell is to last as long as possible.

Typically, narrowboats are painted with 3 additional coats on top of a “blacking” layer (often a bitumen or coal-tar based paint); the Primer, the Undercoat and the Topcoat.

The Challenge

AGM was approached in early 2020 by the owner of a narrowboat named “DRAGONFLY”, looking to reduce the corrosion appearing across its hull.

Proof of Concept

Initially, AGM’s experienced chemists developed a Genable HC Primer in-house, which was applied to a small patch of the narrowboat alongside a commercially available primer.

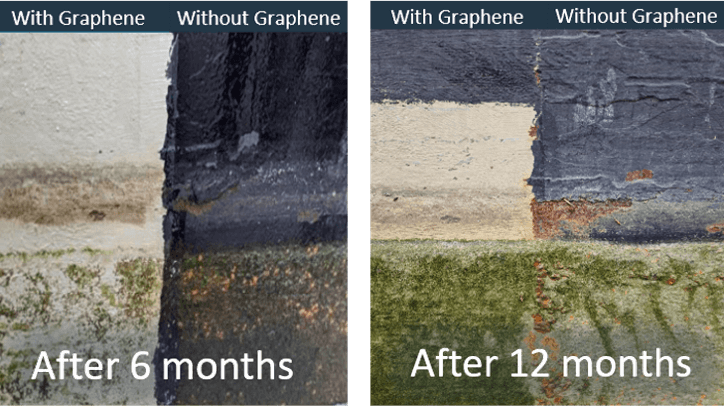

After 6 and 12 months of being on the water, the innovative Genable HC Primer performed significantly better than a commercially available offshore CX primer:

- No corrosion spots or signs of blistering.

- Superior adhesion properties.

- Tough, abrasion resistant finish.

On the back of these extremely positive results, the AGM team returned to sandblast and re-paint the complete hull of the narrowboat, in order to compare the longer-term anti-corrosion performance of its new primer against alternative coating formulations.

A Comparison of Anti-Corrosion Coatings

In May 2021 DRAGONFLY’s hull was painted in 3 sections. Two coats of Genable HC Primer were applied to a larger section of the narrowboat, alongside the commercial primer as a control.

As an additional comparison, the commercial primer was modified with an AGM graphene dispersion and applied to a third section of the hull. A freshly coated “DRAGONFLY” then returned to the water once again!

UPDATE: July 2022 – 14 Month’s Later

The AGM team was invited back to inspect the hull of “DRAGONFLY” and review the condition of the coated sections after over a year being submerged in the waters of Britain’s canal network.

As a performance comparison, the three coated sections were assessed for levels of corrosion, hardness, visual blistering and discolouration.

… And More Positive Results!

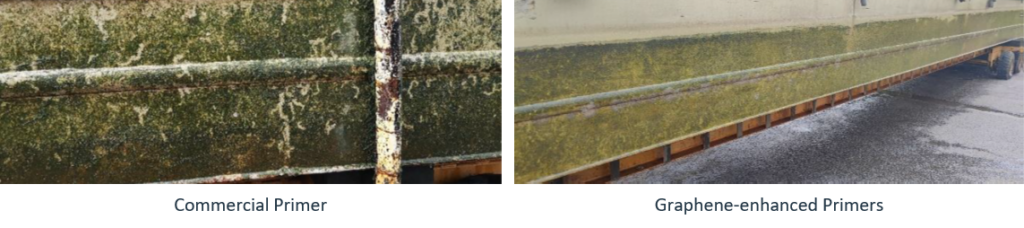

After being jet washed, both graphene systems also demonstrated greater corrosion resistance, with areas on the hull painted in the commercial primer showing signs of exposed metal where adhesion was affected and the coating had come away.

Increased rust damage was also seen along the weld lines and bottom edge of this side, whereas the graphene-enhanced coatings were still intact in all of these key vulnerable areas.

Shore D hardness was also recorded above and below the waterline on each section of the painted hull after cleaning. The graphene-containing paints showed a marginally greater harness than the standard control.

Graphene in Synergy

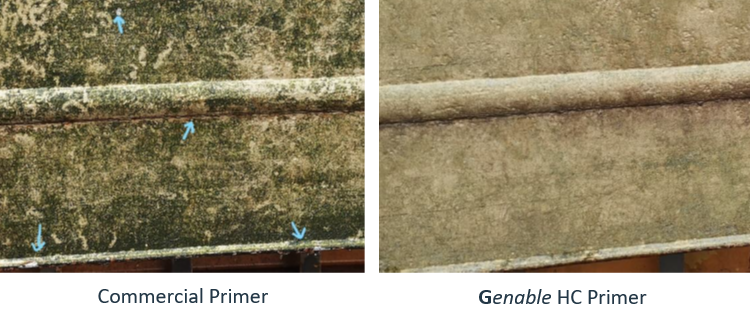

An interesting observation for the Technical team during this visit was the direct comparison of the Genable HC Primer against the commercial primer that had been modified with an AGM graphene dispersion.

Aside from slight discoloration and foul staining, there was minimal difference in performance between the two graphene-based coating systems. As a result of adding just a small amount of AGM graphene dispersion into the existing formulation, no corrosion was visible and the hull coating was undamaged.

This demonstrates the significant impact that graphene can have in combination with other chemistries in extending the life of a coating and protecting the coated asset.

Graphene synergies allow users to get the best of both active and barrier additives and benefit from enhanced corrosion protection. AGM research has shown that the synergies enabled through adding graphene offer extended durability for potential coating applications in harsh C4 and C5 environments.

We’d like to thank the owner of “DRAGONFLY” for their support with this ongoing project and look forward to the next visit!

Learn more about the anti-corrosion benefits of incorporating an AGM graphene dispersion into your coating here or speak to an AGM chemist here.