Standalone Corrosion Protection

AGM uses patent-protected technology to produce both the standard Genable product ranges and custom dispersions to meet everyone’s needs.

- Easy to handle and incorporate into existing industrial systems

- Long-term stability of standard dispersion products

- Optimised dispersion properties design for specific final application

- Enabling industry to benefit from the potential of graphene in a simple, safe and easy to formulate way.

Why innovate with graphene?

Adding graphene as a complimentary additive to the existing range of anti-corrosion products can extend the life of these coatings. Incorporating a graphene nanoplatelet dispersion from AGM is simple – just add and stir!

You can offer your customers a heavy metal free, environmentally friendly alternative to zinc based chemistry.

Working with AGM adds value for you as the coating innovator, as well as extending the service life of the coated asset – A true Win-Win!

Customer Success Stories

Halfords Graphene Anti-Corrosion Primer

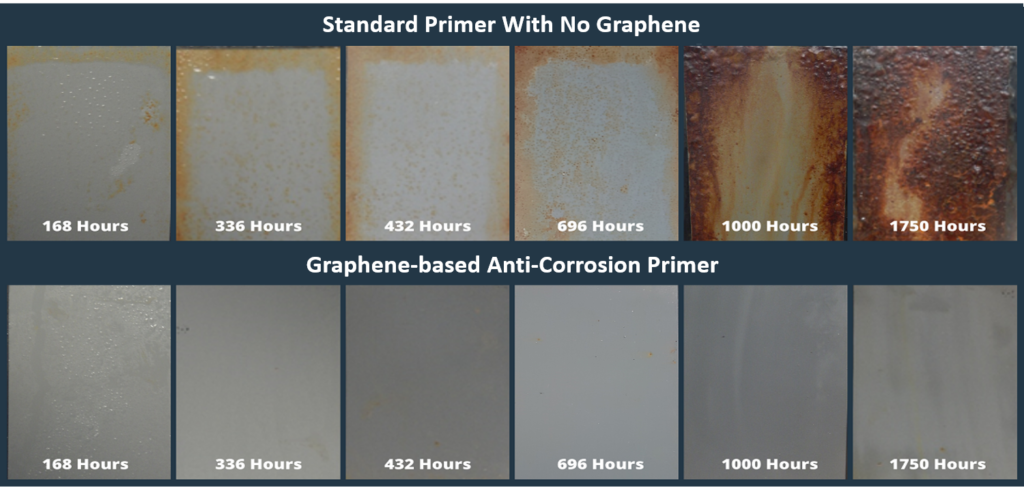

The customer identified an innovative way to improve their existing primer paint for automotive repair applications, which was a basic vinyl/acrylic based paint with limited anticorrosion performance.

AGM’s Genable dispersion was tested at loading levels between 5% to 20% w/w on the total formulation and a successful corrosion primer was developed for sale through industry-leading Halfords Stores and Online.

- Outstanding Anti-Corrosion Protection

- No Impact on other Physical Properties

- Easy to Use and Economically Viable for the DIY Consumer

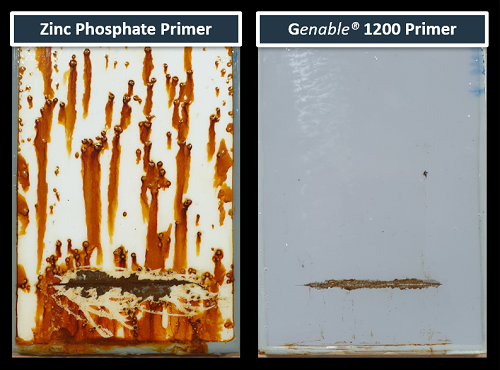

HYCOTE Graphene Anti-Corrosion Primer

Utilising AGM’s graphene nanoplatelet technology, innovative company James Briggs launched an automotive anti-corrosion respray primer offering market-leading performance.

- Increased Corrosion Resistance by 300%

- Zinc Free – no Zinc Phosphate or other heavy metals

- Excellent Adhesion and Flexibility

Following the completion of the formulation development work, AGM continued to support James Briggs’ development with a forerunner to our Innovation Accelerator development programme by running the coated panels in AGM’s prohesion salt spray cabinet – the result was OUTSTANDING.